We are a machine and process engineering company from Noormarkku with an extensive background in manufacturing. Our company was founded in 2016. We serve customers all over the world, and hardware designed by us can be found on almost every continent in the world.

Decades of experience in various industries are strongly reflected in our engineering and design work. We do not develop hardware solely based on theoretical knowledge – we also solve practical problems that may not be thought of without having hands-on experience in the field. And while well planned is half done, we take responsibility for our projects from start to finish by bringing our experience to hardware installation and commissioning as well.

We planned the dry end modernisation of Stora Enso’s pulp dryer. The project was implemented by mapping the customer’s needs, taking into account possible problem areas. The work included planning the scanner installation, changes to the tail end, tail threading equipment, and the modernisation of the sheet cutter.

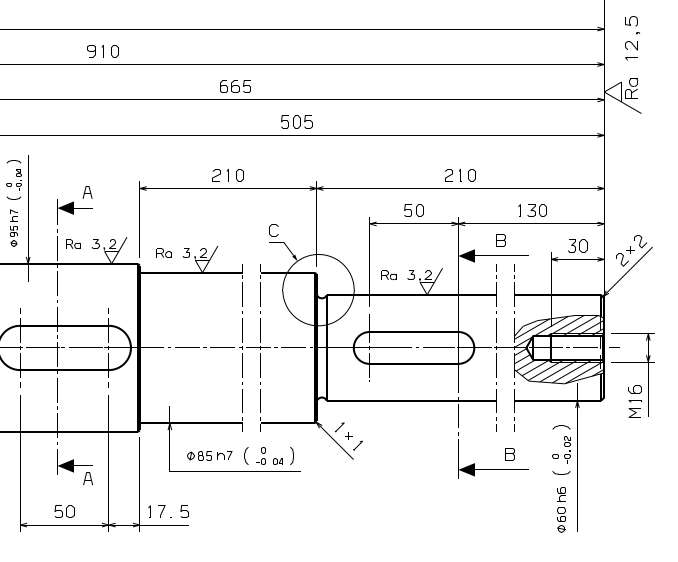

Development of the pulp dryer’s tail threading equipment. Based on solutions adopted in our previous work, we carried out large-scale product development for the customer’s delivery project. In these new types of solutions, we focused on improving the functionality and manufacturability of parts.

Troubleshooting to improve runnability. Runnability did not meet expectations after the modification work carried out by our customer. We mapped the operational problem areas and implemented the necessary changes to the device mechanics and the automation system.

Two of the world’s largest pulp dryers in Indonesia supplied by our customer. We made final mechanical adjustments to the dry end and performed commissioning tests all the way to the start of production.

Tight schedules should not compromise quality. In addition, it is important that the parts fit into place as planned at the place of installation. We carried out quality inspections for the hardware we designed for Metsä Fibre.

Juha-Pekka Kisonen

Design Engineer, Installation Supervisor